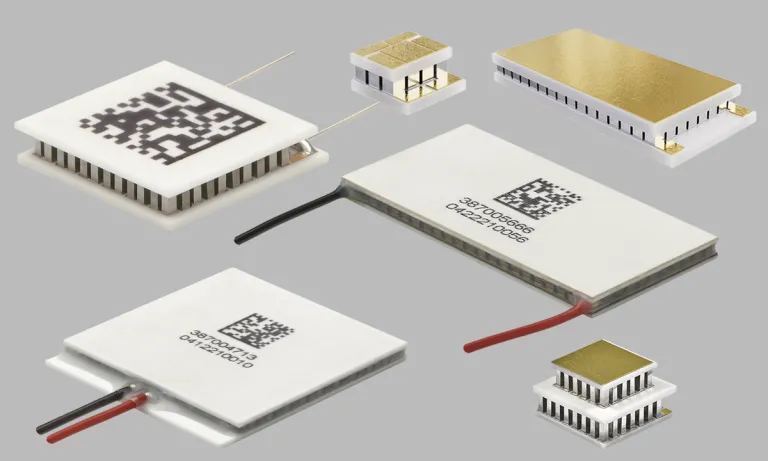

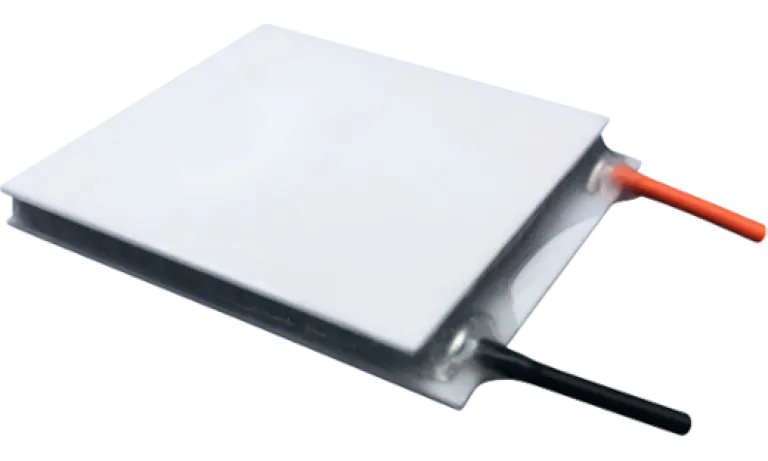

Thermoelectric Coolers

Tark Thermal Solutions’ broad family of thermoelectric coolers provide design engineers with a wide range of cooling capacities, temperature differentials, form factors, finishing options and thermal cycling capabilities. Select from our standard thermoelectric cooler products or engage with our thermal experts to quickly develop a custom thermoelectric cooling solution with our prototyping center for the optimum thermal management solution.

Product Series

Parametric Search

**At least one stage must be selected to see results in chart

* Specifications are shown at a hot side temperature of 27°C, except for the ETX, HTX and PCX series which are shown at 50°C.

About Thermoelectric Coolers

Thermoelectric Cooling Technology

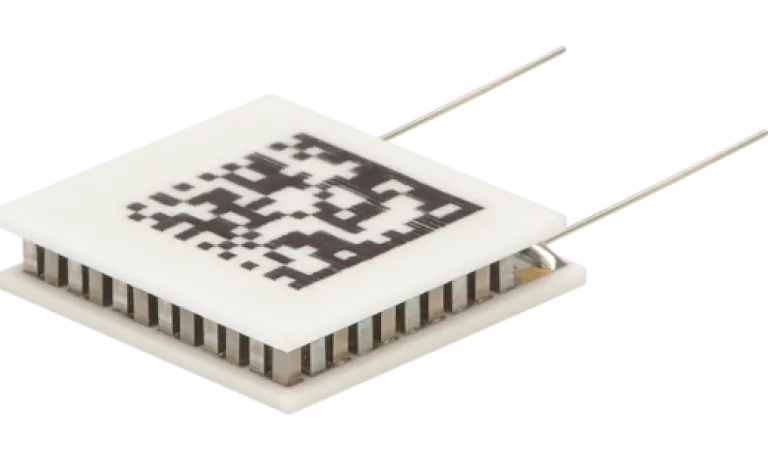

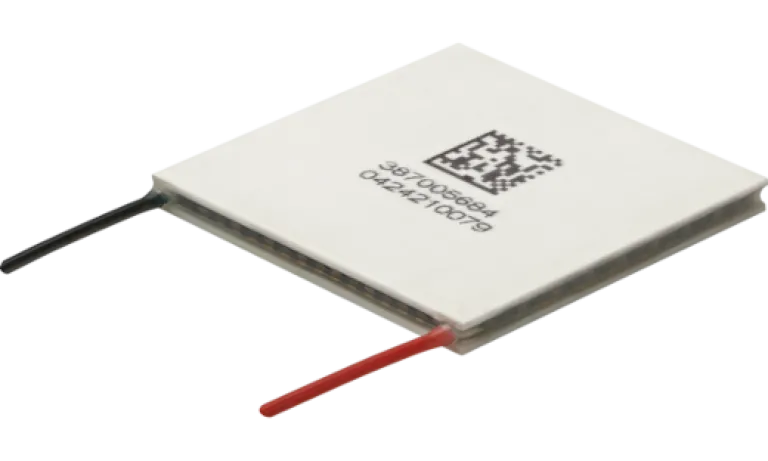

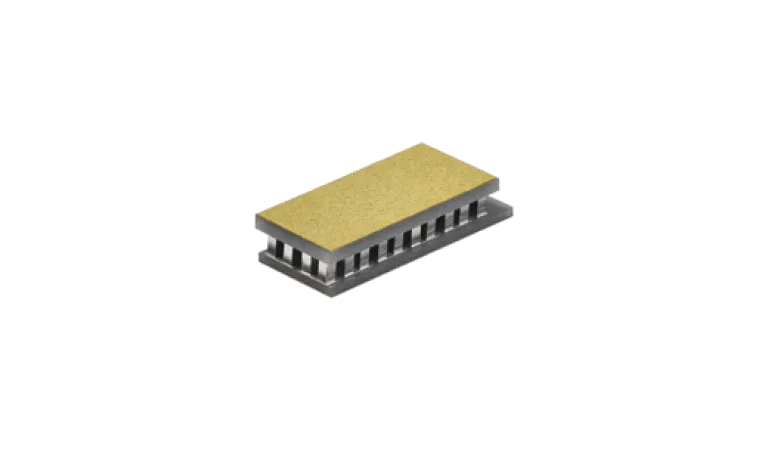

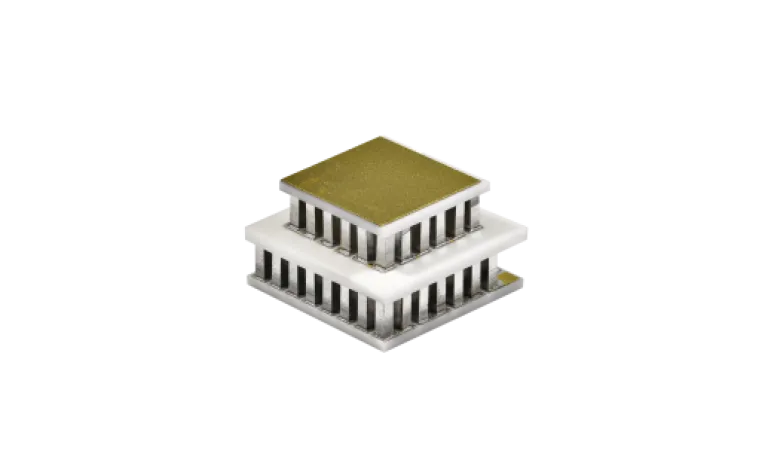

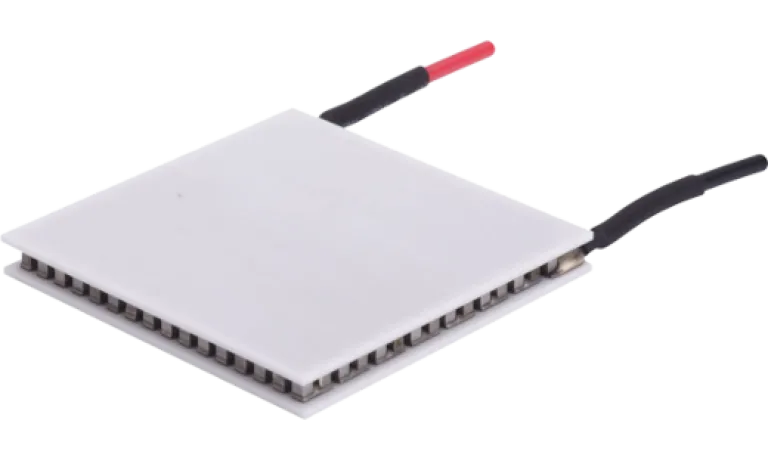

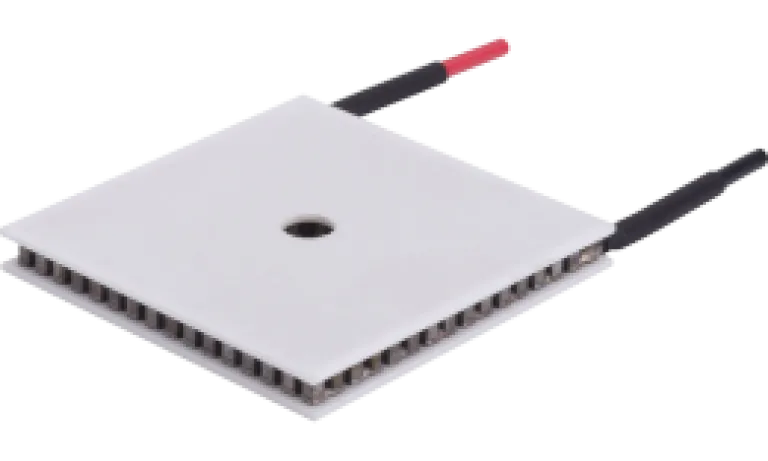

Solid-state heat pumps have been in existence since the discovery of the Peltier effect in 1834. The devices became commercially available several decades ago with the development of advanced semiconductor thermocouple materials in combination with ceramics substrates. Thermoelectric coolers are solid-state heat pumps that require a heat exchanger to dissipate heat utilizing the Peltier Effect. During operation, DC current flows through the thermoelectric cooler to create heat transfer and a temperature differential across the ceramic substrates, causing one side of the thermoelectric cooler to be cold, while the other side is hot. A standard single-stage thermoelectric cooler can achieve temperature differentials of up to 70°C.

The geometric footprint of a standard thermoelectric cooler can vary from 2 x 2 mm to 62 x 62 mm. The small size, combined with lightweight, makes thermoelectrics ideal for applications with tight geometric space constraints and low weight requirements. Traditional cooling technologies, such as conventional compressor-based systems, are typically much larger and heavier compared to thermoelectric technology.

Tark Thermal Solutions thermoelectric coolers can also be used as a power generator by converting waste heat into usable output DC power. Thermoelectrics are ideal for applications that require active cooling below ambient and have cooling capacity requirements <600 Watts. A design engineer should consider thermoelectric coolers when the system design criteria includes such factors as precise temperature control, high reliability, compact geometry constraints, low weight and environmental friendly requirements.

Benefits of Thermoelectric Cooling

Thermoelectric Coolers have several advantages over alternate cooling technologies:

- Solid-state construction features no moving parts resulting in higher reliability.

- Units can be mounted in any orientation.

- Thermoelectric coolers can cool devices down to well below ambient. Colder temperatures can be achieved, down to minus 100°C by using a multistage thermoelectric cooler in a vacuum environment.

- Thermoelectrics can heat and cool by simply reversing the polarity, which changes the direction of heat transfer. This allows temperature control to be very precise, where up to ±0.01°C can be maintained under steady-state conditions.

- In heating mode, thermoelectric coolers are much more efficient than conventional resistant heaters because they generate heat from input power supplied plus additional heat generated by the heat pumping action.

- Devices are environmentally friendly because they use no CFCs and electrical noise is minimal.

- Thermoelectric coolers can be used as energy harvesters, turning waste heat into usable output DC power.