産業用途

産業用レーザー、液体クロマトグラフィー、半導体製造などの産業用機器に求められる冷却能力は、数百ワットから数百キロワットまでさまざまで、必要な温度制御は-80℃から+150℃の範囲に及びます。Tark Thermal Solutionsは、産業用機器の幅広い冷却要件と温度制御要件に対応する、固体サーモエレクトリックと液体冷却の両方のソリューションを提供しています。

アプリケーション概要

Whether used for cutting, welding, micro-machining or drilling, industrial lasers generate a significant amount of heat that needs to be quickly and efficiently dissipated.

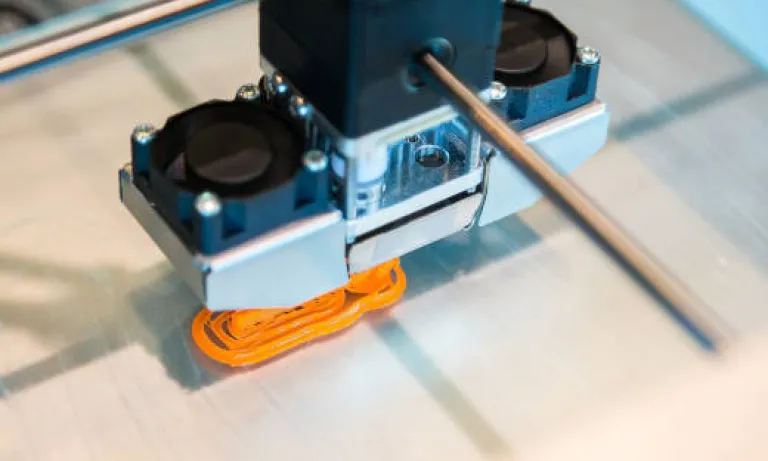

Additive manufacturing, better known as 3D printing allows for rapid prototyping and manufacturing of high-quality final products. 3D printing machines utilize lasers, generating a large amount of heat.

Compared to traditional lamp projectors, laser projectors provide sharper contrasts, wider color range and longer life expectancy.

Machine Vision is a revolutionary technology that enables analysis of a tremendous amount of data.

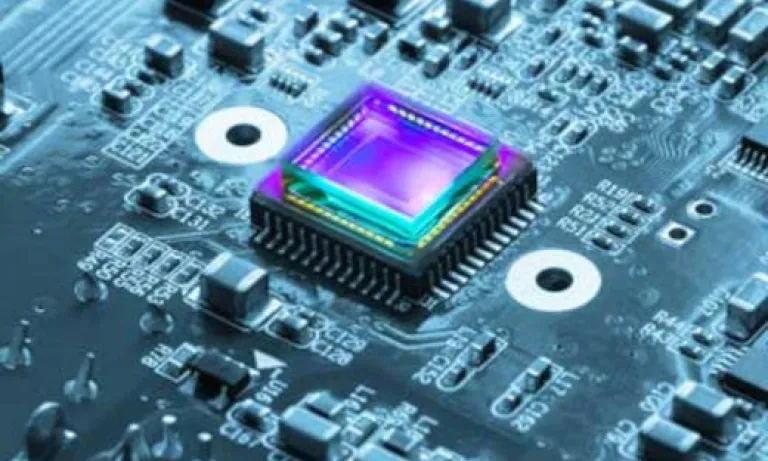

Enhanced CMOS Sensor technology enables the capturing of high-resolution images at fast readout speeds in consumer, industrial and machine-vision applications.

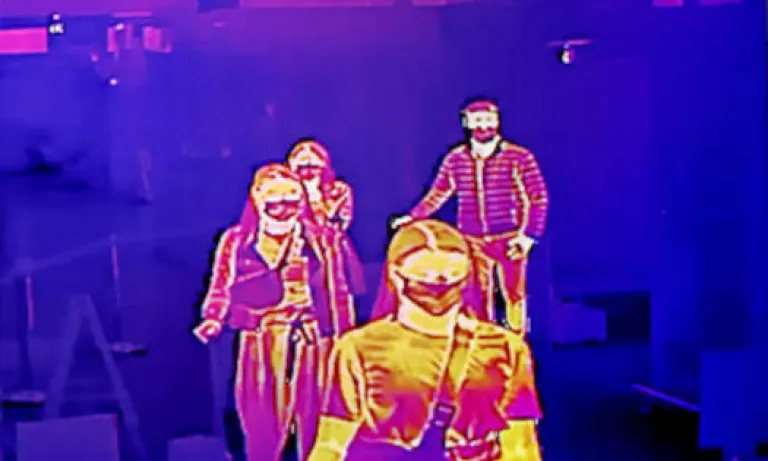

With the ability to detect and convert radiation (heat) into a visual image, infrared range (IR) sensors are used for tracking movement and temperature of humans.

Liquid chromatography is used for analyzing mixtures by separating, identifying, and quantifying their constituent components.

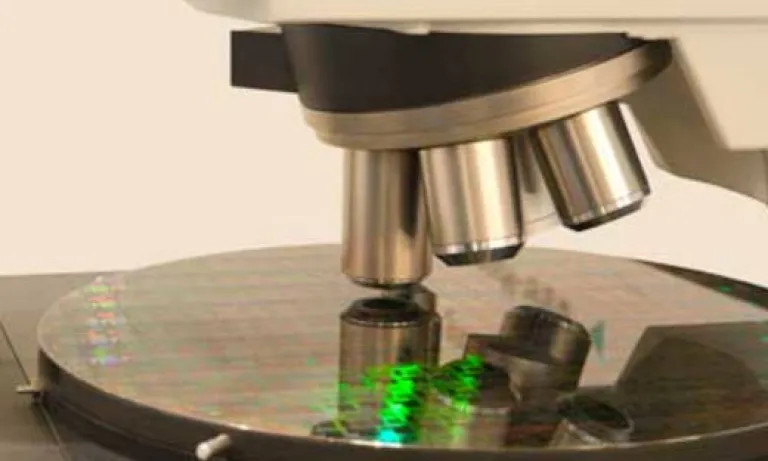

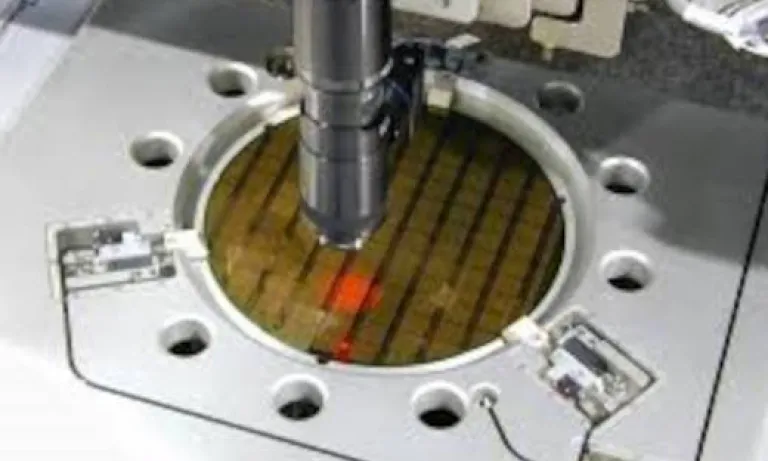

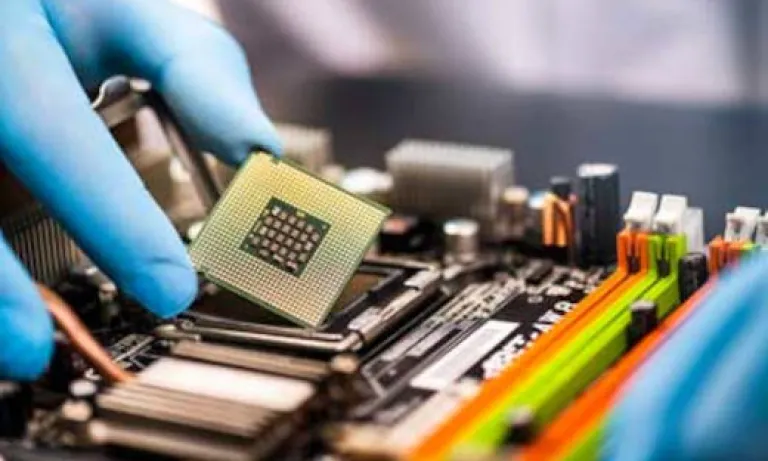

Automated metrology systems are now implemented throughout the semiconductor manufacturing process to find defects and ensure quality of devices.

Critical production tools used in semiconductor fabrication facilities must be reliable and easy to service to minimize downtime.

Thermal test sockets are used in the final stage of the semiconductor manufacturing process to thermally test microchips before assembly into the final product.

Laird Thermal Systems designs and produces high performance, high reliability, cost-effective liquid cooling systems for industrial X-ray scanners.

Corrosion occurs in liquid cooling loops due to chemical, electro-chemical, or abrasive action, caused by the heat transfer fluid on the wetted surfaces.

連絡先

ターク・サーマル・ソリューションズとパートナーシップを結べば、熱の専門家チームが製品性能の最適化、製品のダウンタイムの最小化、省スペース化、消費電力の削減、全体的なコスト削減を支援します。

専任テクニカル・サポート

当社の熱技術専門家が、お客様の用途に最適なソリューションの選択をお手伝いします。

グローバル・サポート・チーム

お客様の次世代製品の市場投入をお手伝いします。

ニュースレター登録

ニュースレターをご購読いただくと、TTSに関するニュースをいち早くお届けします。