Advancements in CDU Pump Technology to Meet the Demands of 75-200 kW Data Center Racks

Introduction

The era of air-only data center cooling is ending. As rack power densities rise into the 75–120 kW range and beyond, data centers are adopting hybrid cooling architectures, where air plays a supporting role and liquid cooling manages the majority of heat generated by modern CPUs, GPUs, and TPUs.

Within this transition, direct-to-chip (D2C) liquid cooling has emerged as a highly efficient and cost-effective solution, delivering predictable heat removal at the source. While technologies such as rear-door heat exchangers and immersion cooling are also in use, D2C continues to gain traction for its balance of performance, scalability, and efficiency.

As cooling distribution units (CDUs) evolve to support high-density racks, one subsystem requires renewed focus: the pump. The choice between centrifugal and positive displacement designs is more than a detail—it directly impacts efficiency, responsiveness to load changes, and the economic scalability of the cooling system.

This paper explores why centrifugal pumps are the optimal solution for modern liquid-cooled CDUs in the 75–120 kW range and beyond, and outlines key design factors that influence performance, reliability, and total cost of ownership.

Key Takeaways for CTOs and Thermal Engineers

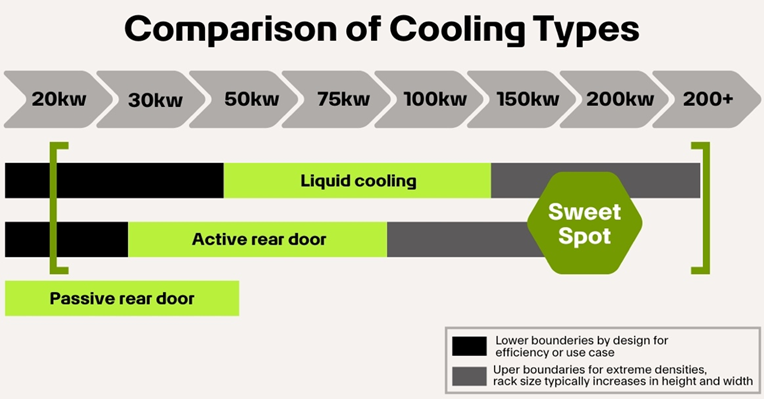

- Liquid cooling is now a necessity, not a luxury. Rack densities beyond 40kW cannot be reliably cooled by air alone. Liquid cooling is becoming essential as densities rise. Traditional air only cooling supports only 20–40 kW per rack, while modern state-of-the-art RDHx technology (rear-door heat exchangers using chilled water) extend this to 50–80 kW. Beyond that, direct liquid cooling is required for reliable operation. Centrifugal pumps enable adaptive flow control for variable compute loads, reducing energy waste and ensuring thermal stability.

- System-level optimization matters. The pump, heat exchangers, and sensors must be engineered as an integrated system to avoid cavitation, vibration, and efficiency losses.

- 50–120 kW CDUs represent the design “sweet spot.” Centrifugal pumps excel in this range, balancing compactness, scalability, and cost-effectiveness.

- In-house engineering (design, prototyping, validation) enables precise control over pump curves, materials, and performance envelopes to meet data-center reliability requirements

- ASHRAE W‑classes define standardized temperature ranges for the water (or coolant) supplied to liquid‑cooled IT equipment, and they give data center designers and operators guidance on setting allowable supply temperatures that directly affect pump performance by reducing ΔT, increasing fluid viscosity, and tightening NPSH margins, which are all critical factors for selecting reliable CDU pump designs. By specifying the minimum and maximum allowable entering water temperatures for each class (such as W32 or W40), these guidelines directly influence pump sizing, materials selection, flow rates, and control strategies. This ensures that coolant can be delivered reliably at the required temperature and pressure even under peak load.

The Efficiency Advantage of Liquid Cooling

Air cooling has served data centers well for decades, but it’s now approaching its thermal management ceiling. Traditional room air cooling struggles beyond ~15–20 kW per rack; rear-door heat exchangers extend this to ~50–80 kW, but AI/HPC racks at 75–120 kW and beyond generally require direct-to-chip (DLC) liquid cooling.

Depending on the specific heat, density and temperature, liquid cooling has 3,500x higher heat capacity than air at 20 C, (ASHRAE TC 9.9, 2024) dramatically improving thermal efficiency and enabling denser compute without the penalties of excessive airflow. By moving the heat removal point closer to the chip, D2C systems minimize temperature gradients and allow consistent inlet temperatures even as rack power rises.

The 50–120 kW CDU “Sweet Spot”

In this range, pump behavior defines system balance. Too much pressure leads to wasted power and potential seal wear, and too little flow risks hotspots and cavitation.

A properly selected centrifugal pump ensures stable, efficient operation across load transients, whether cooling a compact 50 kW AI training rack or a 120 kW HPC enclosure. By maintaining predictable pressure and flow characteristics, centrifugal CDUs deliver consistent coolant temperature and extend server lifespan.

Application Profile:

- Rack density: 50–120 kW (≥75 kW typical for AI/HPC)

- Flow range: 38-303 L/min (10-80 G/min) depending on operating conditions, ΔT, pressure, and coolant properties

- Operating medium: Water/glycol (75/25 typical)

- Design focus: Low Net Positive Suction Head (NPSH), high MTBF, minimal footprint

- Pump type: Centrifugal

- Primary benefits: High flow efficiency, reliability, adaptability

The Rise of High-Density Racks

- Early 2000s: 2-5 kW per rack

- 2010-2020: 10-20 kW per rack for enterprise compute

- 2025: 100 kW AI clusters, HPC, and edge deployments regularly exceed 100 kW per rack

- 2030: Projected to be >250 kW per rack

This exponential rise in thermal density has outpaced incremental improvements in air-cooling. To sustain performance, thermal engineers must now optimize every subsystem within the liquid cooling loop, including the CDU pump, which governs the flow and stability of the entire system.

In addition to thermal requirements, assembly considerations play a role when optimizing for an efficient cooling solution. For example, outgassing is not acceptable because it can coat the imaging sensor optics. It is therefore vital to properly select thermal interface materials between the thermoelectric cooler and CMOS sensor with low outgas characteristics or substitute interface material, all together with a pre-tin solder on hot and cold surfaces of the thermoelectric cooler. Design considerations need to be made to minimize thermal shorting. This occurs when cold side surfaces come in contact with hot side surfaces which causes the thermoelectric cooler to draw more current to achieve the same cooling performance.

At these densities, CDU performance directly impacts server uptime, PUE, and total system efficiency. Selecting the right pump technology is essential to achieving both performance and reliability targets.

Centrifugal vs. Positive Displacement Pumps

Why Centrifugal Wins for CDUs

Positive displacement (PD) pumps, such as gear or diaphragm types, maintain fixed volumetric output and are well-suited for high-pressure, low-flow applications. However, in a data center liquid cooling context where system pressures are relatively low and flow modulation is critical, PD pump constant-flow rigidity becomes a drawback for variable loads.

Centrifugal pumps, by contrast, convert rotational energy from an impeller into fluid velocity, naturally adapting to system resistance. This yields:

- Smooth flow at high volumes delivering large amounts of coolant, ensuring uniform temperature control across many direct-cooled chips

- Energy efficiency since centrifugal pumps handle low-viscosity fluids typical of D2C cooling systems, resulting in lower power consumption and operational cost

- Superior efficiency in the 38-303 L/min (10–80 G/min) flow range typical of 40-120kW CDUs

- Low maintenance and higher reliability due to few moving parts, reduced wear, lower vibration and quieter operation

- Lower cost of ownership due to lower-cost construction, lower up front cost, lower maintenance expenses

|

|

Centrifugal pumps offer the best performance-to-cost ratio for liquid-cooled data center applications, particularly where compactness and variable thermal loads are key.

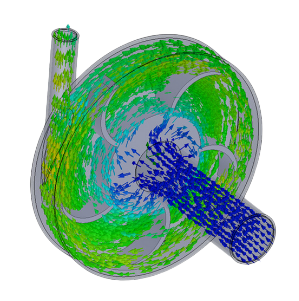

Inside the Centrifugal Pump

At the heart of a centrifugal pump lies the impeller and volute assembly, which accelerates the liquid radially outward from the center of rotation. Pressure builds as velocity energy is converted to static pressure within the volute casing, creating continuous, controllable flow.

At the heart of a centrifugal pump lies the impeller and volute assembly, which accelerates the liquid radially outward from the center of rotation. Pressure builds as velocity energy is converted to static pressure within the volute casing, creating continuous, controllable flow.

This inherently smooth, pulseless flow enables fine-tuned control via variable-frequency drives (VFDs) and sensor feedback. As CDU systems become more intelligent integrating temperature, flow, and pressure sensors, the centrifugal pump’s modulatable flow characteristics become even more advantageous.

Design Insight: Impeller geometry directly defines head and flow characteristics. Tark Thermal Solutions’ internal design and prototyping ensure each pump meets targeted performance curves for 50-120kW rack applications.

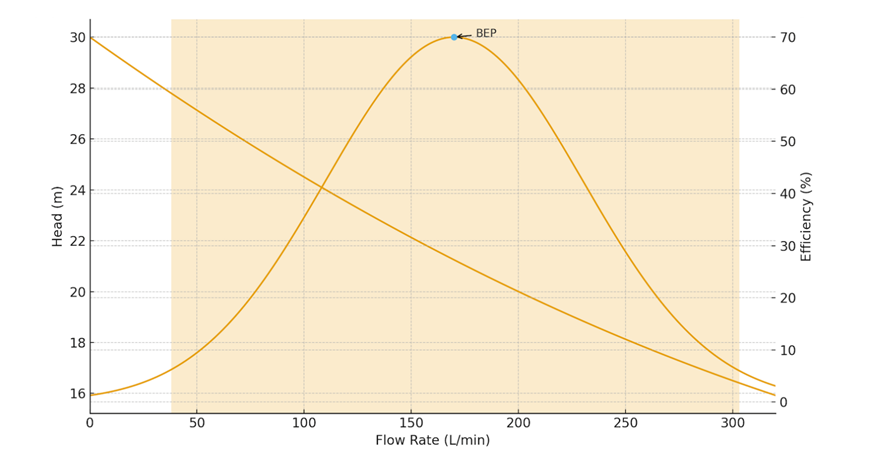

The pump performance curve below highlights the BEP over the expected 38-303 L/min (10-80 G/min) operating band with a requirement of ≥10–20% NPSH margin at worst-case temp/altitude.

Seal strategy: Offer no-seal magnetic-drive option to minimize leak risk; otherwise, specify mechanical seal type/materials compatible with glycol mix and additives.

Materials: Wetted parts (SS316L, engineered polymers), ceramic bearings, corrosion inhibitors compatible with glycol.

Cleanliness & filtration: 50–100 µm Y-strainers at inlets; side-stream filtration; air separators/degassers to avoid cavitation and micro-bubbles.

Redundancy: N+1 pumps with auto-failover; isolation valves and quick-disconnects for serviceability.

Controls: VFD tied to ΔT and differential pressure setpoints; low-NPSHa/air-ingress alarms; flow, pressure, temp sensors at CDU inlet/outlet and at manifold branches.

Vibration/Acoustics: Define acceptable vibration (per ISO 10816/20816 classes) and noise targets for rack-adjacent deployments.

Compliance: Note ASHRAE W-class design point (e.g., W32/W40/W45) and facility interface (supply/return temp, pressure, water chemistry).

Engineering and Reliability Considerations

Cavitation prevention: Optimized inlet geometry and material selection protect against vapor formation in low-pressure zones.

Material compatibility: Stainless steels, engineered polymers, and ceramic bearings ensure long life in mixed-fluid environments (water/glycol).

Compact form factor: Integration-friendly footprints fit modern CDU cabinets without sacrificing flow headroom.

Thermal endurance: Pumps designed for 24/7 operation at elevated coolant temperatures maintain performance over millions of cycles.

Scalable output: Configurable designs support flows from 10 to 60 GPM, covering the 50–120 kW thermal range common to D2C CDUs.

Tark Thermal Solutions pump modules are qualified for continuous operation under load, pressure, and temperature cycling representative of Tier 3+ data center environments.

Conclusion: Rethinking Pump Performance for the Liquid-Cooled Future

The data center landscape is evolving faster than traditional thermal architectures can adapt. As rack densities surge 75–120 kW and higher, air cooling alone cannot keep pace. The transition to D2C liquid cooling is inevitable, and with it comes a new performance frontier for CDUs.

Right-sizing centrifugal pumps to operate around BEP for 60–80% of duty hours, with ≥10–20% NPSH margin, typically delivers lower energy use, reduced seal/bearing wear, and higher MTBF than oversizing or PD alternatives in low-viscosity loops.

By rethinking the pump at the heart of the CDU, engineers can unlock higher efficiency, improved reliability, and scalable cooling capacity for next-generation data center environments.

Tark Thermal Solutions’ centrifugal pump technology, developed and tested in-house, is engineered precisely for this challenge, combining proven hydraulic performance with the compactness and efficiency modern data centers demand.