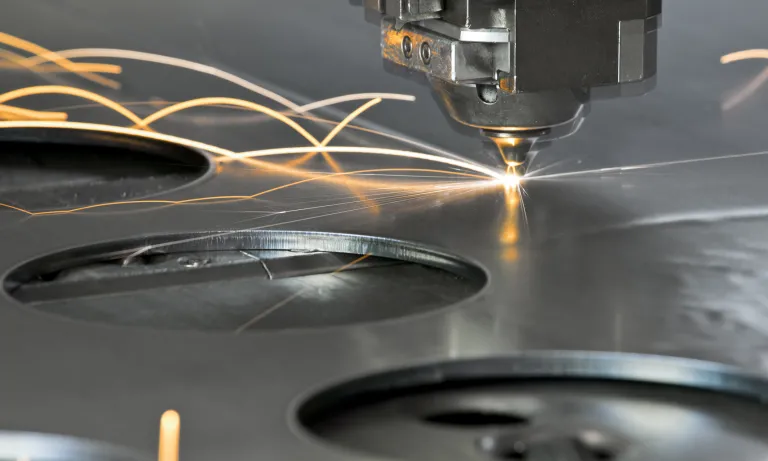

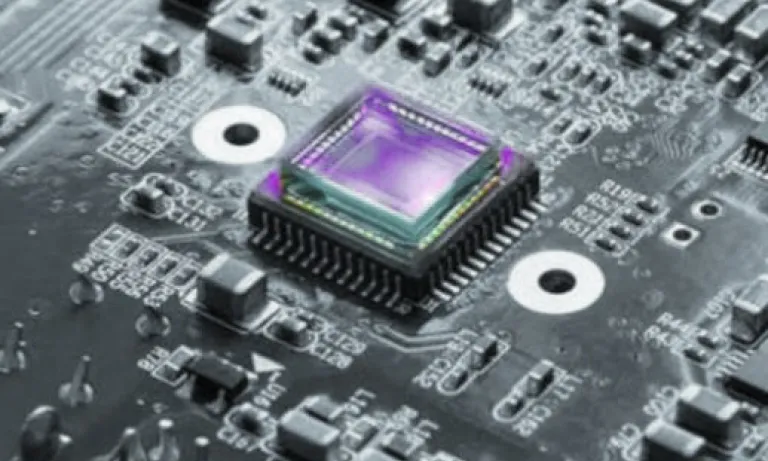

Industrial Applications

The cooling capacity demands for industrial equipment, such as industrial lasers, liquid chromatography, and semiconductor fabrication, can vary from a couple of hundred Watts to hundreds of Kilowatts with required temperature control ranging from -80°C to +150°C. Tark Thermal Solutions' offers both solid-state thermoelectric and liquid cooling solutions that address the wide range of cooling and temperature control requirements for industrial equipment.

Application Overview

Get in touch

Partner with Tark Thermal Solutions and our team of thermal experts will help you optimize your product performance, minimize your product downtime, reduce space, reduce power consumption or reduce your overall cost.

Dedicated Technical Support

Our technical thermal experts can help you select the best solution for your application.

Global Support Team

We are ready to help bring your next-generation product to market.

Sign Up for Newsletter

Subscribe to our newsletter and be the first to receive all the news about TTS.