Industrielle Anwendungen

Leistungsstarkes Wärmemanagement für industrielle Hochleistungsanwendungen

Industrielle Anlagen stellen extrem unterschiedliche und anspruchsvolle Anforderungen an das Wärmemanagement. Der Kühlleistungsbedarf reicht von einigen hundert Watt bis zu mehreren hundert Kilowatt, während gleichzeitig präzise Temperaturregelungen von etwa −80 °C bis +150 °C erforderlich sein können.

Tark Thermal Solutions bietet ein breites Portfolio an thermoelektrischen Festkörperkühllösungen sowie Flüssigkeitskühlsystemen, um diese große Bandbreite industrieller Kühl- und Temperaturregelungsanforderungen zuverlässig abzudecken. Unsere Lösungen kommen weltweit in industrie- und produktionskritischen Anwendungen zum Einsatz, bei denen Zuverlässigkeit, Präzision und Betriebssicherheit entscheidend sind.

Anwendungsübersicht – Industrielle Märkte & Systeme

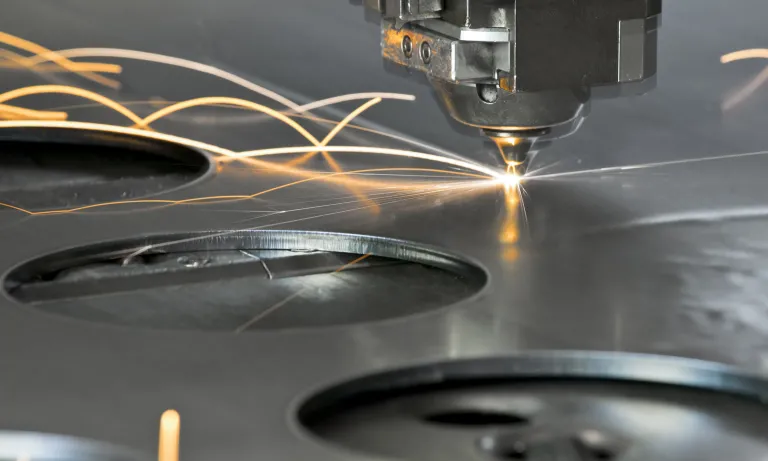

Industrielaser erzeugen beim Schneiden, Schweißen, Bohren und bei der Mikrobearbeitung sehr hohe Wärmelasten, die schnell und zuverlässig abgeführt werden müssen, um Leistung, Strahlqualität und Lebensdauer zu sichern.

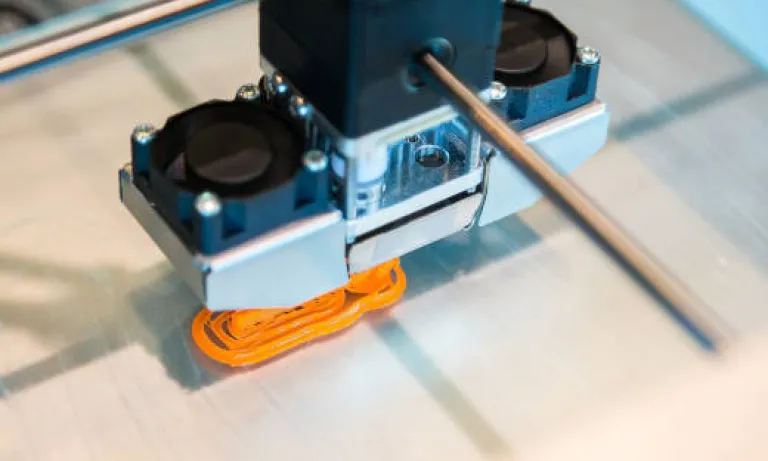

Die additive Fertigung erfordert eine präzise Temperaturkontrolle von Laserquellen, Elektronik und Prozesskammern, um gleichbleibende Materialeigenschaften und Prozessstabilität zu gewährleisten.

Laserprojektoren bieten gegenüber Lampenprojektoren höhere Helligkeit, besseren Kontrast und längere Lebensdauer – erfordern jedoch effiziente, kompakte Kühllösungen für Laserdioden und Optiken.

Machine-Vision-Systeme verarbeiten große Datenmengen in Echtzeit. Eine stabile Temperaturführung ist entscheidend für Bildqualität, Sensorleistung und Systemzuverlässigkeit.

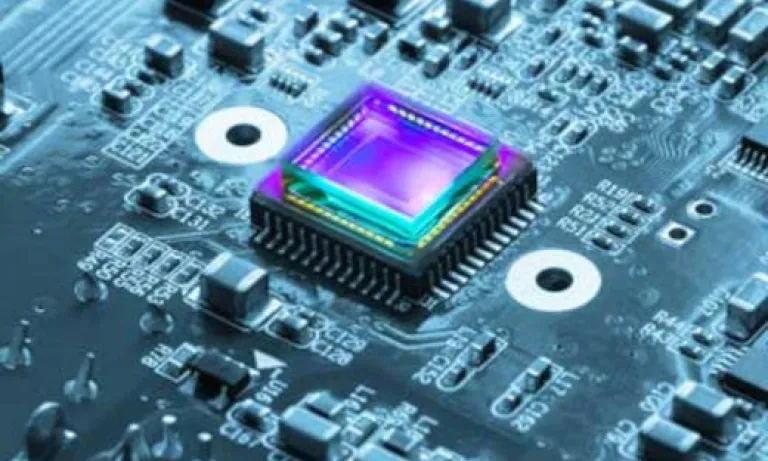

Moderne CMOS-Sensoren kommen in Industrie, Konsumgütern und im maschinellen Sehen zum Einsatz. Thermisches Management reduziert Rauschen und verbessert die Bildqualität.

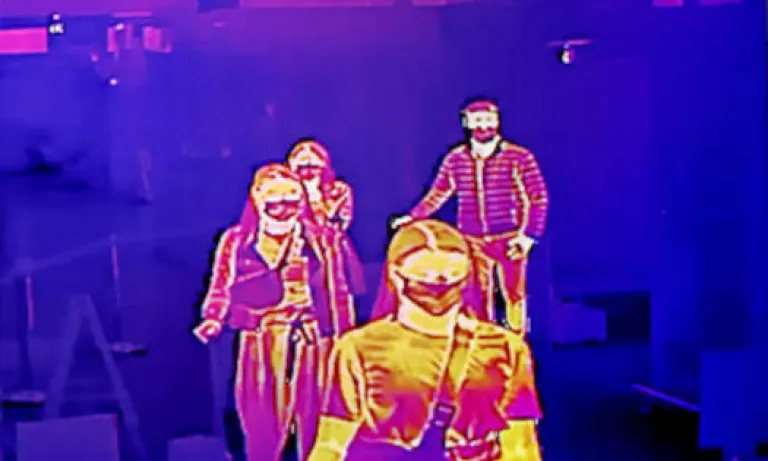

IR-Sensoren erfassen Wärmestrahlung und werden zur Temperaturüberwachung, Prozesskontrolle und Sicherheit eingesetzt. Thermische Stabilisierung ist entscheidend für Messgenauigkeit.

In industriellen Analyseprozessen ist eine reproduzierbare Temperaturkontrolle entscheidend für Trennleistung und Messergebnisse.

Automatisierte Messsysteme prüfen Wafer und Bauteile auf Defekte. Präzise Temperaturregelung ist entscheidend für Messgenauigkeit und Prozessstabilität.

Produktionsanlagen in der Halbleiterfertigung müssen hochzuverlässig, wartungsarm und temperaturstabil arbeiten, um Ausfallzeiten zu minimieren.

Thermische Testsockel ermöglichen das gezielte Heizen und Kühlen von Chips in der Endprüfung – mit hohen Anforderungen an Dynamik und Genauigkeit.

Industrielle Röntgenscanner erzeugen große Energiemengen, von denen der Großteil als Wärme abgeführt werden muss, um Systemleistung und Sicherheit zu gewährleisten.

Korrosion kann die Lebensdauer von Flüssigkeitskühlsystemen erheblich verkürzen. Spezifische Kühlkreislaufkonzepte und Materialauswahl sind entscheidend.

Kontaktieren Sie uns

Unser Team von Spezialisten hilft Ihnen dabei, die Leistung Ihrer Produkte zu optimieren, Ausfallzeiten zu minimieren, Platz zu sparen, den Stromverbrauch zu senken und Ihre Gesamtkosten zu reduzieren.

Technischer Support benötigt?

Unsere Experten können Sie bei der Auswahl der besten Lösung für Ihre Anwendung unterstützen.

Ihr Kontakt zu uns

Wir helfen Ihnen, Ihr Produkt der nächsten Generation auf den Markt zu bringen.

Anmeldung zum Newsletter

Abonnieren Sie unseren Newsletter und erhalten Sie als Erster alle Neuigkeiten über TTS.